Views: 41 Author: Site Editor Publish Time: 2023-05-30 Origin: Site

Insert bearings are crucial in various industries, providing efficiency, versatility, and improved application performance.

From heavy machinery to automotive systems, these essential components are designed to meet customers' specific needs, enhancing productivity and reducing downtime.

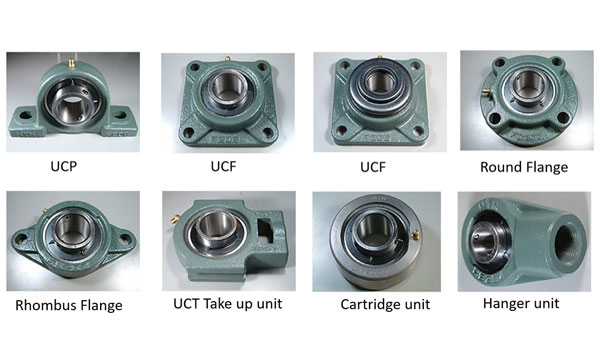

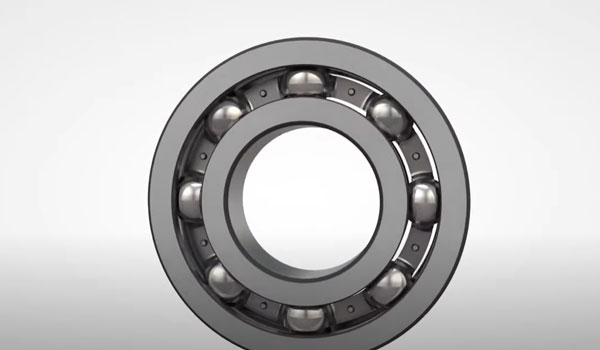

Insert or mounted or bearing units are specialized rolling element bearings. Easily inserted into housings or structures, simplifying installation, removal, and replacement processes. Comprising a rolling bearing and housing, insert bearings provide a stable, low-friction surface for smooth motion and

support rotating shafts.

Insert bearings find application in various industries, including agriculture, construction, food processing, mining, and more. These bearings are used in various equipment, such as :

● Conveyors

● Pumps

● Fans

● Agricultural machinery

● Household appliances

Their ability to withstand heavy loads, accommodate misalignment, and operate in diverse environments makes them indispensable in industrial settings.

Insert bearings come in different types, each designed to meet specific requirements and applications. Understanding the various types can help customers choose the appropriate insert bearings for their industrial needs. Here are some common types of insert bearings:

Radial insert bearings are designed to support radial loads, which are forces acting perpendicular to the shaft's axis. These bearings have an extended inner ring that enables them to accommodate misalignment and provide reliable performance in applications with

moderate to high radial loads.

Self-aligning insert bearings are specially designed to compensate for shaft misalignment. They feature a spherical outer ring that allows the bearing to adjust its position relative to the shaft, accommodating angular misalignment. This type of insert bearing is suitable for applications where shaft deflection or misalignment is expected.

Eccentric collar insert bearings have an eccentric locking collar mounted on the inner ring. This collar grips the shaft eccentrically, providing a secure fit and preventing the bearing from slipping on the shaft. Eccentric collar insert bearings are commonly used in applications where frequent repositioning or adjustment of the bearing is required.

Set screw insert bearings feature a set screw tightened against the shaft to secure the bearing in place. The set screw applies pressure on a flat surface or a small groove on the shaft, creating a tight grip. These bearings are easy to install and suitable for lower loads and moderate speeds applications.

Adapter sleeve insert bearings are used in applications requiring larger shaft diameters. They consist of a standard insert bearing combined with an adapter sleeve. The adapter sleeve adjusts the bearing to fit the shaft diameter accurately.

Spherical outer ring insert bearings have a convex outer ring that provides self-alignment and enables the bearing to compensate for misalignment and shaft deflection. These bearings are commonly used in applications with high misalignment or heavy loads.

Stainless steel insert bearings are manufactured using corrosion-resistant stainless steel materials. These bearings are suitable for applications where moisture, chemicals, or corrosive substances are present, ensuring long-lasting performance and durability.

● Customers searching for insert bearings aim to improve performance and efficiency by reducing friction and wear.

● These bearings minimize vibrations, ensuring smooth rotation and reducing noise levels.

● Enhanced system stability and increased overall productivity are additional benefits that resonate with customers.

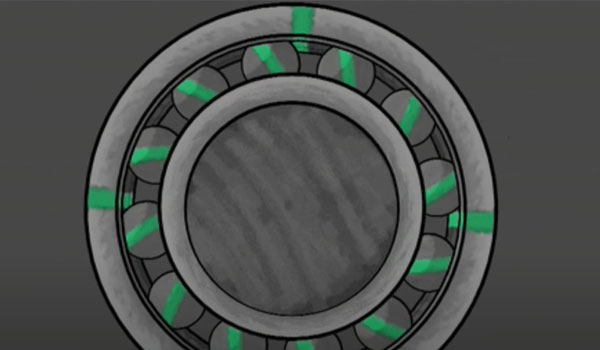

Insert bearings contribute to improved performance and increased efficiency. They improve energy efficiency and extend equipment life by reducing friction and wear. The minimization of vibrations ensures smooth rotation, resulting in reduced noise levels. Additional benefits gained from insert bearings are enhanced system stability and increased overall productivity.

● Customers seek to insert bearings because they can be customized to meet specific application requirements, providing tailored solutions.

● Available in various sizes, configurations, and sealing options, insert bearings offer seamless integration into existing systems or new equipment design, aligning with customers' needs for adaptability.

Insert bearings offer customization options to meet specific application requirements. A range of sizes, configurations, and sealing options are available, making them versatile and adaptable. This adaptability enables seamless integration into existing systems or new equipment design, ensuring optimal performance and compatibility.

● Customers appreciate inserting bearings for easy maintenance, enabling quick replacement or re-lubrication when necessary.

● Regular maintenance and proper lubrication significantly extend the service life of insert bearings, preventing costly downtime.

● With proper care, these bearings can withstand demanding operating conditions, ensuring durability that customers value.

Insert bearings are designed for easy maintenance, providing convenience in replacement or re-lubrication when necessary. Regular maintenance and proper lubrication significantly extend their service life, preventing costly downtime. With their robust construction and proper care, insert bearings can withstand demanding operating conditions and deliver long-lasting performance.

When selecting insert bearings, customers should consider several factors to ensure the best fit for their application:

● Load capacity: Customers searching for insert bearings should consider the bearing's ability to handle the expected load, ensuring reliable performance.

● Speed requirements: The bearing should be suitable for the desired rotational speed of the equipment to maintain optimal operation.

● Temperature range: Customers need to ensure that the chosen insert bearings can operate within the required temperature range of their specific application.

● Environmental conditions: When selecting insert bearings, factors such as moisture, dust, and corrosive substances in the operating environment should be considered.

Insert bearings play a vital role in various industries, offering efficiency, versatility, and enhanced application performance. Customers seeking to insert bearings aim to optimize equipment performance, improve productivity, and minimize downtime. By understanding why customers search for insert bearings and addressing their specific needs, we can provide useful and interesting information to our audience.

By carefully considering their requirements and consulting with industry experts or bearing manufacturers, customers can make informed decisions to maximize the benefits of insert bearings. Ultimately, insert bearings are indispensable components that enhance efficiency and productivity across different industrial sectors.

Related Post might be HELPFUL to your Business: Where to buy cost-effective spherical roller bearings in the us?

Insert Bearings: Enhancing Eff

Insert Bearings: Enhancing Eff

Where to buy cost-effective sp

Where to buy cost-effective sp

How To Choose the Right Deep G

How To Choose the Right Deep G

Roller Bearings: The Unsung He

Roller Bearings: The Unsung He